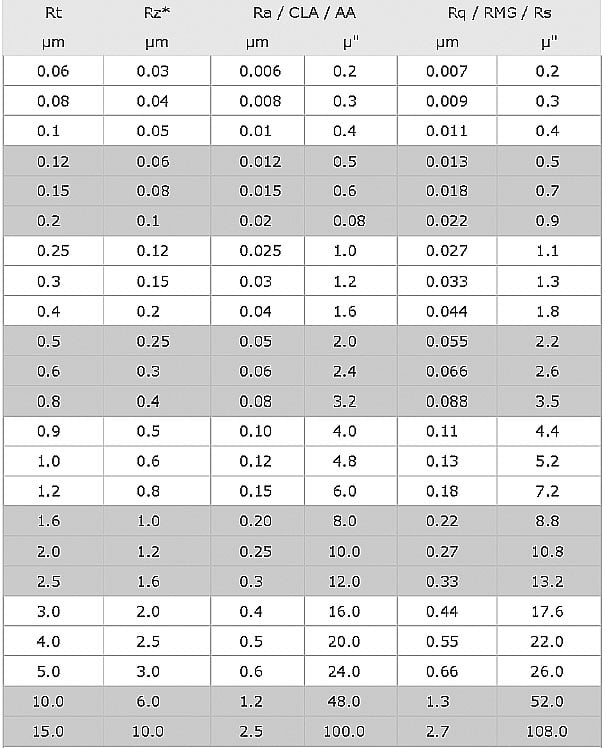

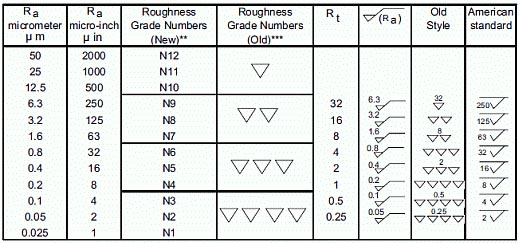

A Complete Guide To Understand Surface Roughness In Manufacturing - LEADRP - Rapid Prototyping And Manufacturing Service

Xometry Europe - 💢 Selecting the right surface roughness for #cncmachined parts can be confusing. That is why we have made a guide for you to be able to select the best

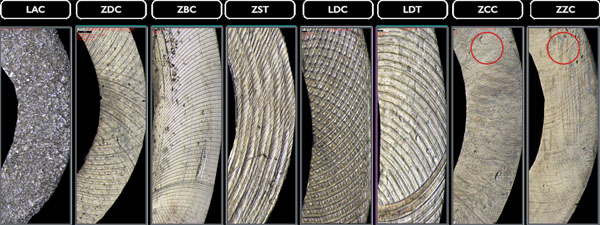

Machines | Free Full-Text | A GAN-BPNN-Based Surface Roughness Measurement Method for Robotic Grinding

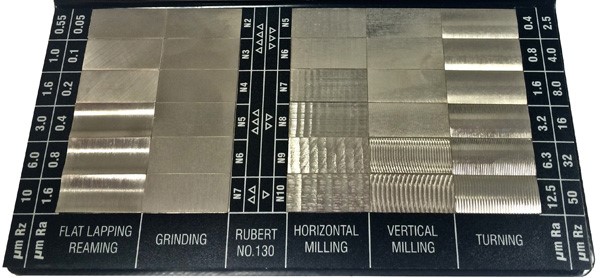

Alternative Surface Roughness Measurement Technique for Inaccessible Surfaces of Jet Engine Parts Using the Rubber Silicon Replica Method | SpringerLink